So I couldn't really find much on this, so I figured I would try to get some info and pics up. I will be grinding a bit more off later, I can tell there needs to be a bit more trimmed, but I think we did a good job, considering we had nothing to go off of besides sketchy online info and what little I could get from a few phone calls late last night.

First we noticed that a notch needed to be cut in order for the protrusion on the bj to fit properly on top of the LCA

we did clean it up some, we actually ended up grinding down right to the aluminum blocks that go inside the LCA.

Once we got the spindle mocked up, I couldn't see where and why people were needed to grind down right were the bj shaft goes into the spindle, mine completely cleared. I think guys were putting the bolts in wrong and needed clearance. That's the only think I can think of, or their bj was different...

as you can see we ground down the "valleys", or what I like to call them anyway. Basically we cut some down, cleaned it up, mocked it back up, swung it around, then did more until we felt comfortable. I DID NOT cut the steering stops off on my LCA. I was told to do it by a few, and a few said no. I decided to leave them for now just to be safe.

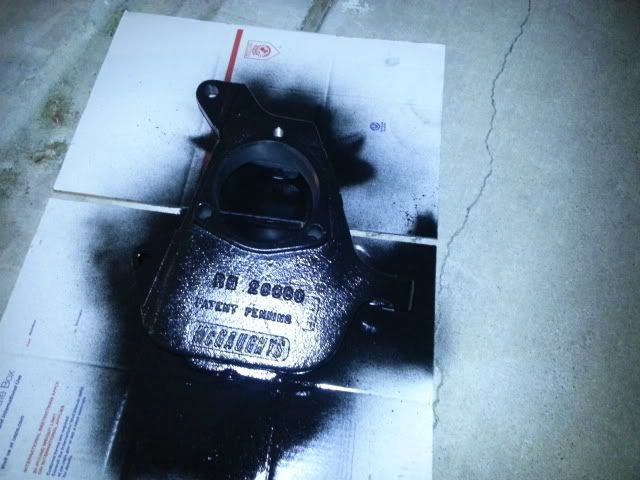

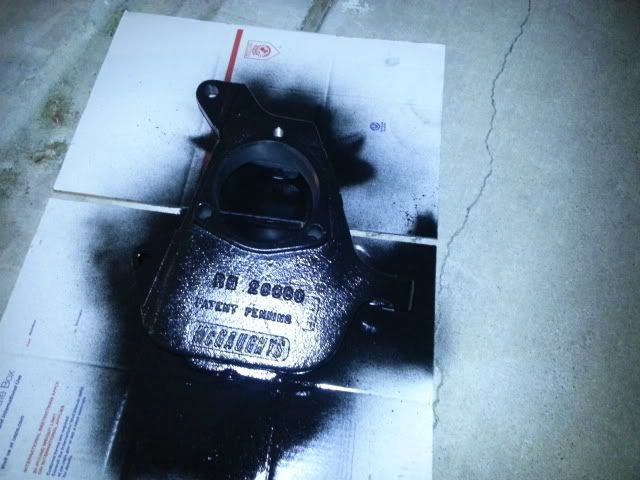

Nothing fancy, just Rustoleum. Guy at Road Armor actually told me they use it for touch-ups on powdercoatings...so I just used a can I had laying around.

First we noticed that a notch needed to be cut in order for the protrusion on the bj to fit properly on top of the LCA

we did clean it up some, we actually ended up grinding down right to the aluminum blocks that go inside the LCA.

Once we got the spindle mocked up, I couldn't see where and why people were needed to grind down right were the bj shaft goes into the spindle, mine completely cleared. I think guys were putting the bolts in wrong and needed clearance. That's the only think I can think of, or their bj was different...

as you can see we ground down the "valleys", or what I like to call them anyway. Basically we cut some down, cleaned it up, mocked it back up, swung it around, then did more until we felt comfortable. I DID NOT cut the steering stops off on my LCA. I was told to do it by a few, and a few said no. I decided to leave them for now just to be safe.

Nothing fancy, just Rustoleum. Guy at Road Armor actually told me they use it for touch-ups on powdercoatings...so I just used a can I had laying around.

Last edited: